Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

Headlights in cars manufactured twenty or even ten years ago are noticeably different from those produced today. Modern low-beam lights increasingly focus on illuminating the road ahead while reducing glare for other drivers. While this may improve road safety, it creates a new issue: overhead and roadside traffic signs get less direct light, making them harder to see.

Poor visibility of critical signage can lead to missed warnings, missed exits and late decision-making, increasing the potential for accidents. For this reason, sign sheeting needs to keep pace with the automotive industry.

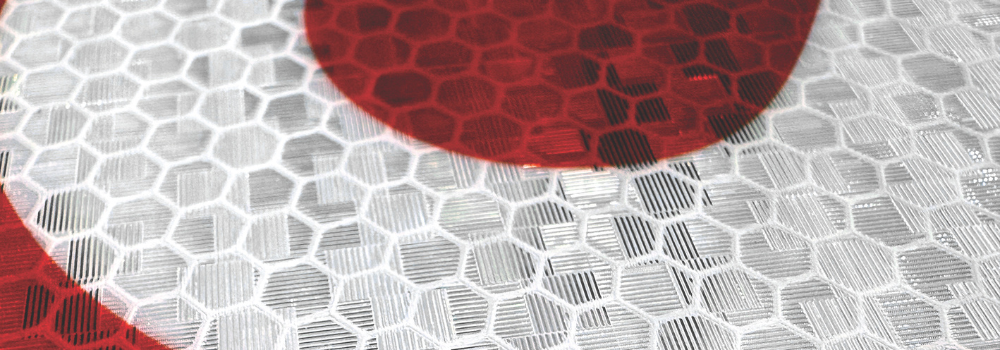

AS/NZS 1906.1 standard Class 1100 microprismatic cube-corner retroreflective sheeting (previously called Class 1W) is solving this problem by offering advanced photometric performance, durability and safety.

It works by reflecting light through tiny, precisely engineered prisms arranged in a specific geometric pattern, each with three perpendicular faces that form a cube corner. When light from vehicle headlights hits the surface of these cubes, the three mirrored surfaces inside them reflect the light back toward the source, regardless of the angle at which the light enters. This makes the signage highly visible even at night or in low-light conditions.

Adrian Caruana, Blackwoods Signage Operations Manager, explains,

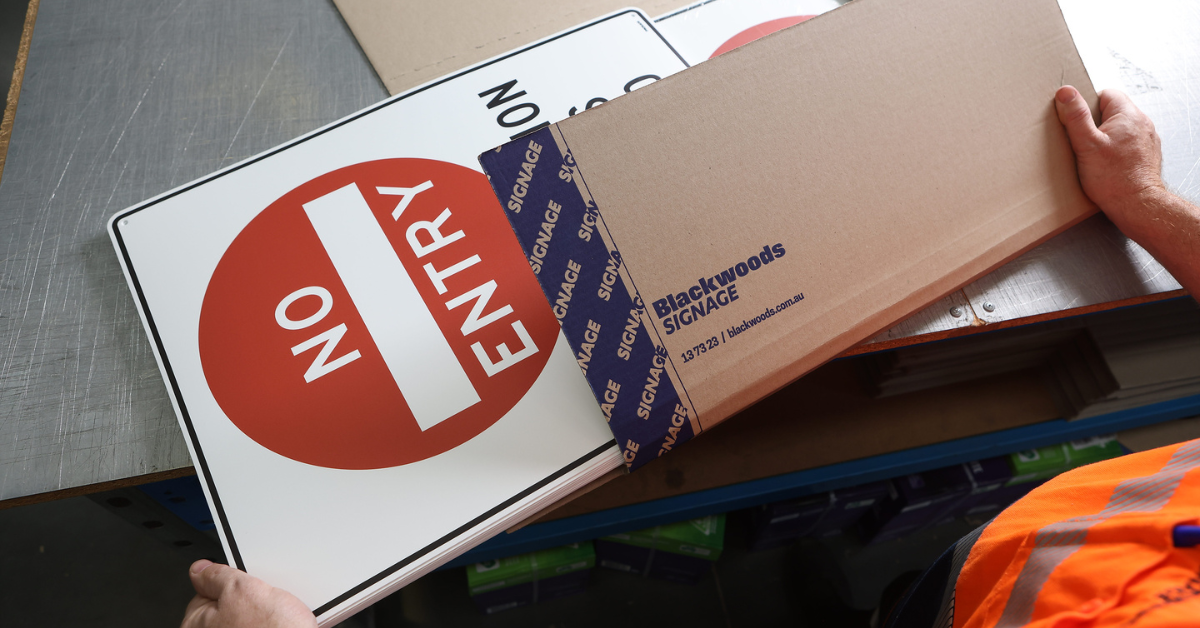

“Unlike lower ratings, Class 1100 sheeting works exceptionally well at long distances, wide angles and even under challenging conditions, such as rain or fog, where traditional reflectivity might drop. This improved visibility of road signs allows drivers to see and react more quickly and safely. The sheeting is also available with both anti-graffiti and anti-dew overlay films.”

Our Blackwoods Class 1100 sheeting is built to withstand tough conditions, lasting much longer than traditional signage materials (up to 15 years). This means you’ll need fewer replacements, making it more cost-effective over the long term.

Caruana notes,

“These days, our customers have the choice of either an anti-graffiti or anti-dew overlay. The anti-graffiti option reduces taxpayer funds spent cleaning graffiti from signs, while the anti-dew overlay is perfect for enhancing sign reflectivity during dew events.”

If you want better performance, greater visibility and safety, as well as increased durability for your signage, get in touch with your Blackwoods Technical Safety Specialist today.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...