Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

Good risk management starts with identifying hazards in the workplace, determining the level of harm they could cause and taking steps to reduce the risks they present. The hierarchy of safety controls provides a framework to help employers make these decisions.

Here are some tips for implementing the hierarchy - and how Blackwoods can help with safety solutions tailored to individual workplaces across a range of industries.

The five levels of the hierarchy are:

When it comes to making decisions about hazards and risks, it’s not necessarily a matter of using one level or another. The solution might involve a combination of two or more levels to create a robust and effective system for managing risk and improving health and safety.

The onus is on employers to be proactive in reducing risks and keeping workers as safe as possible. This is important not only to meet compliance and other legal requirements, but to help reduce the risk of costly insurance claims, reputational damage and lost productivity.

Here are five ways to implement safety controls in the workplace:

Conduct a thorough risk assessment of the workplace, starting with identification of hazards and determining the degree of harm they could cause. The key here is not to come up with unlikely scenarios but to identify hazards likely to cause a significant level of harm.

Make hazard elimination the goal where possible, since this offers the greatest protection. But if this isn’t possible, consider how to implement a substitution. Some examples include:

Where elimination or substitution are not possible, modifying the workplace environment can reduce exposure to hazards. Here are some examples:

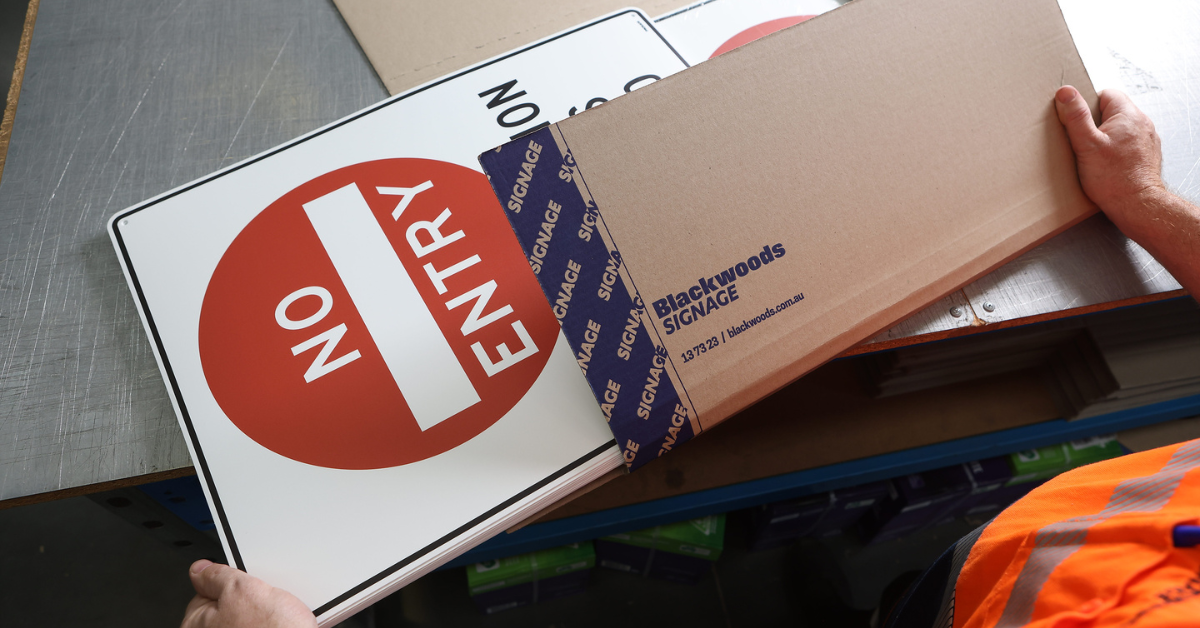

Workers should not only be trained in how to do their job, but also in recognising hazards and following safe practices. It’s important to develop sound safety processes and procedures at the management level, and to communicate these effectively across the worksite – e.g. through safety signage.

PPE is always an important component of workplace safety solutions. But in some cases, it’s a critical first line of protection. For example, a study of welders across Australia showed that the most effective solution for reducing welders’ personal exposure was a welding helmet with a Powered Air Purifying Respirator (PAPR).

Assessing hazards and risks then implementing safety controls can be challenging. The right solution for each workplace depends on the particular industry, business operations, environment and hazards.

Blackwoods Category Manager - Workplace Safety Darren Gallagher says the Blackwoods Assess, Inform and Equip approach can help employers implement a full solution. “Utilising our knowledge and experience across industrial, engineering, and safety products, and supported by our technical specialist teams, we can deliver more effective solutions using an integrated approach across the different levels of control,” he says. “Making your business safe and protecting your people is about much more than just PPE.”

Get in touch to find out how Blackwoods can support employers in optimising workplace safety.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...