Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

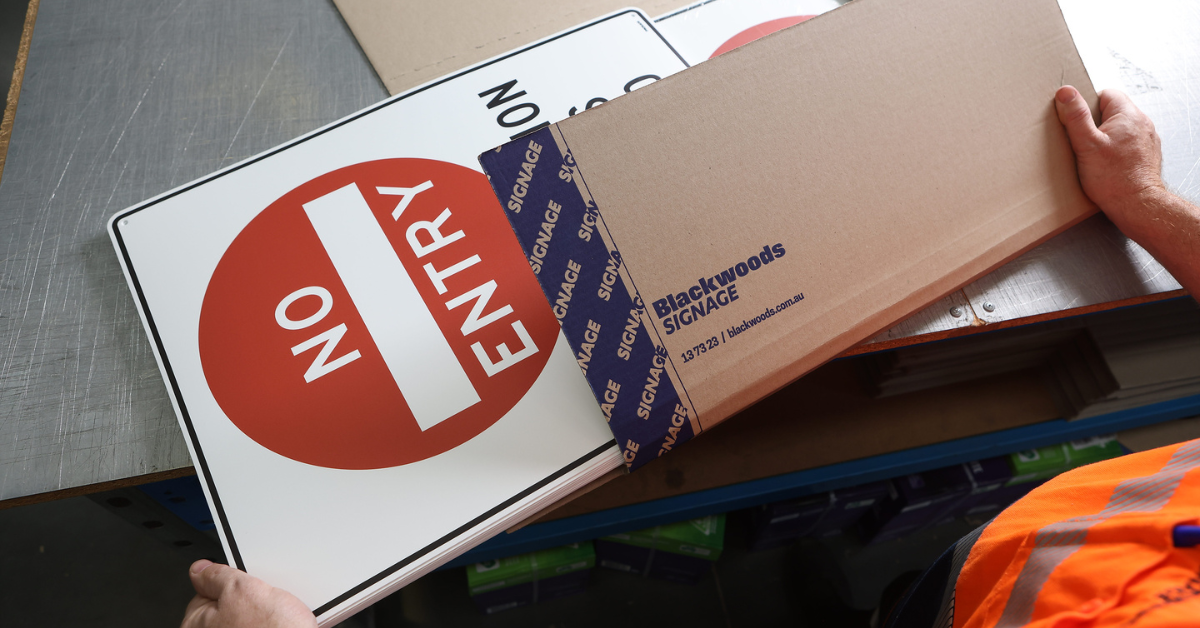

Safety signs are not just a regulatory requirement, but a vital tool for informing and providing clear direction and warnings in the workplace, helping prevent accidents and injuries. In addition to maintaining a safe workplace, conducting regular site surveys ensures compliance to regulatory obligations, and validation of sign selection, proximity to hazards and effectiveness.

A survey involves a comprehensive visual assessment of all safety signs within a workplace. It includes checking for signs that are missing, non-compliant with AS 1319, damaged, faded or obscured, and ensures that existing and new hazards are appropriately identified, communicated and mitigated. Areas where safety signs are typically required to maintain a safe and compliant workplace include

|

Area |

Description |

|

Entrances and Exits |

Signs indicating emergency exits, fire exits, and no entry zones. |

|

Hazardous Areas |

Areas with potential dangers such as chemical storage, electrical rooms, and machinery zones. |

|

Work Zones |

Areas where specific tasks are performed, like construction sites, manufacturing floors, and loading docks. |

|

Restrooms and Break Areas |

Signs for hygiene practices, such as handwashing instructions and no smoking signs. |

|

Stairways and Elevators |

Warning signs for slippery steps, load limits, and emergency procedures. |

|

Parking Lots and Driveways |

Signs for speed limits, pedestrian crossings, and parking regulations. |

|

First Aid Stations |

Locations of first aid kits, defibrillators, and emergency contact information. |

|

Fire Safety Equipment |

Locations of fire extinguishers, fire hoses, and alarm points. |

|

Restricted Areas |

Areas that require special access or protective equipment, such as labs, clean rooms and high-risk environments |

|

General Safety Information |

Signs for PPE requirements, safety procedures, and emergency assembly points. |

|

Storage Areas |

Signs indicating the contents, such as flammable materials, heavy loads, or hazardous substances. |

|

Confined Spaces |

Warnings about entry restrictions and necessary precautions for confined spaces. |

|

Walkways and Corridors |

Directional signs, warnings for low ceilings, and reminders to keep pathways clear. |

|

Maintenance Areas |

Notices about ongoing maintenance work, lockout/tagout procedures, and equipment safety. |

|

Environmental Hazards |

Areas prone to flooding, high noise levels, or extreme temperatures. |

|

Visitor Areas |

Instructions for visitors, such as check-in procedures, PPE requirements, and safety briefings. |

|

Waste Disposal Areas |

Signs for proper disposal of different types of waste, including recycling and hazardous waste. |

|

Emergency Response Areas |

Locations of emergency showers, eyewash stations, and spill kits. |

|

Security Zones |

Areas with surveillance, restricted access, and security protocols. |

|

Temporary Hazards |

Signs for temporary conditions like wet floors, construction zones, or temporary detours. |

When conducting a survey, considerations include anything that may prevent a safety sign from effectively communicating the intended message. This includes everything from identifying and replacing damaged or outdated signs, to ensuring images and colours are vibrant and contrast well with the background to enhance and ensure visibility.

The size of the sign and the text should be appropriate for the viewing distance, with larger signs and bigger text necessary for areas where the sign needs to be seen from a distance. Signs should be placed at eye level and in locations where they are easily visible, avoiding areas where they might be obscured by equipment or other objects.

A survey involves five easy steps.

Adrian Caruana, Blackwoods Signage Manager, puts it simply:

“Properly placed and maintained safety signs can significantly reduce the risk of accidents,” says Adrian Caruana. “They provide clear instructions and warnings, helping to prevent injuries and save lives. Routine safety signs surveys keep safety at the forefront within the workplace.”

At Blackwoods, we are committed to helping our customers maintain a safe workplace. Our team of experienced technical safety specialists is available to assist you in conducting comprehensive safety sign surveys.

In addition, our wholly-owned Blackwoods Signage manufacturing operation delivers flexible and tailored in-house end-to-end signage solutions throughout Australia. From product selection identification and recommendations to tailored graphic solutions and manufacture, our team is available to assist in a timely manner to keep your employees, visitors and the community safe.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...