Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

1 min read

Blackwoods

:

28 January 2026

Blackwoods

:

28 January 2026

Two large manufacturing facilities were facing mounting challenges in managing their industrial consumables and personal protective equipment (PPE). Manned stores required dedicated staff to receive and issue goods, while multiple free-issue stores across the sites led to uncontrolled spending, stock hoarding, and zero visibility of inventory holdings. Workers frequently lost valuable time searching for the right items, and manual procurement processes added layers of inefficiency and cost.

These issues weren’t just operational; they were costing the business hundreds of thousands annually in lost productivity and poor working capital management.

To address these challenges, the facilities partnered with Blackwoods to implement a tailored Inventory Solutions strategy. The centrepiece of this transformation was the deployment of vending machines across four strategic locations.

These machines were designed to automate and streamline the distribution of high-usage industrial consumables and PPE. Strategically placed near operational zones, they eliminated the need for manned and free-issue stores, reducing downtime and improving tool time for frontline workers.

The vending machines were integrated with Blackwoods touchless EDI system, enabling automated ordering and seamless restocking by Blackwoods facilitators. Manual processes, from order placement to receipt were consolidated into a single, efficient workflow.

In addition to convenience, the machines provided real-time reporting of online-item usage, giving procurement teams unprecedented visibility into consumption patterns. This enabled tighter budget control and smarter inventory decisions.

The transformation delivered immediate and measurable results:

Blackwoods vending machine solution didn’t just streamline inventory, it revolutionised how these manufacturing sites operate. With automated procurement, real-time visibility, and reduced waste, the facilities unlocked new levels of productivity and cost control.

Explore how Blackwoods Inventory Solutions can transform your business:

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

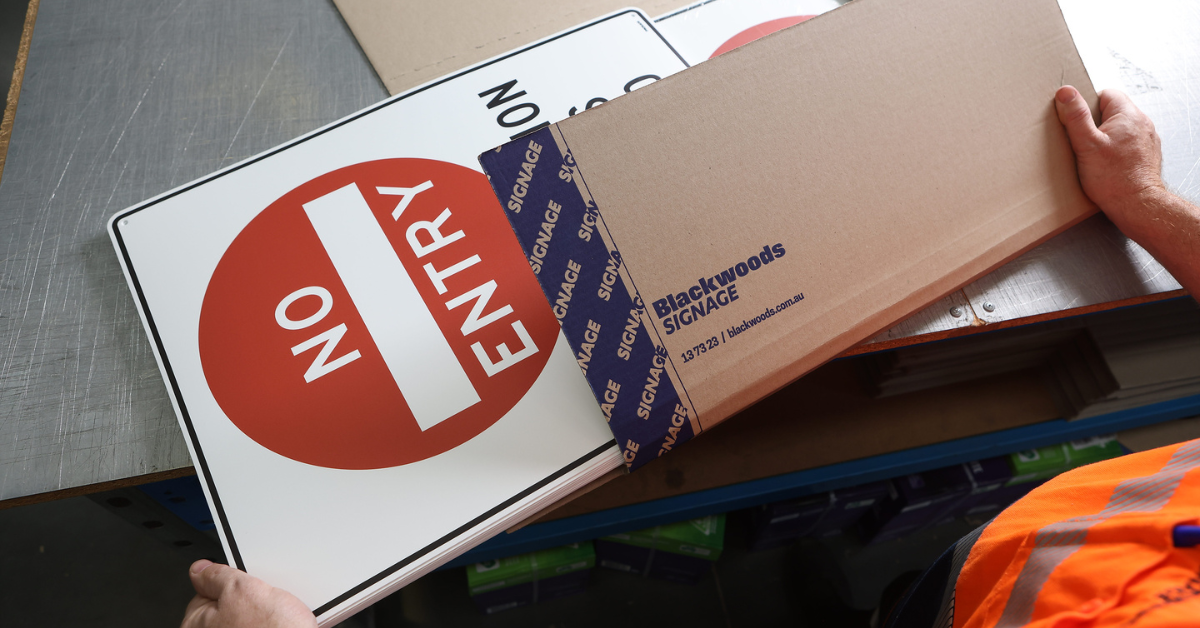

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...

Sometimes, a small act of kindness sets something powerful in motion. Just after the Covid pandemic, the Blackwoods WA sales team felt a desire to...