Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

Kim Cressey has been helping businesses across Victoria and Tasmania for over 17 years, providing tailored uniform solutions through Blackwoods. Her customers range from large energy enterprises to Zoos Victoria, each with unique safety and workwear needs.

She delivers complete packages that include technical advice on fire retardant garments, on-site uniform and footwear fittings, and support with web entitlements—ensuring every team is equipped with the right gear.

Kim works closely with local account managers to understand each customer’s business and uniform requirements. Her experience helps overcome common procurement challenges such as long turnaround times and incorrect orders.

Customers value the reliability and efficiency that Blackwoods brings to the table, making uniform procurement smoother and more accurate.

“Workwear is about keeping people safe but it’s also a huge investment for most businesses,” she says. “We make sure we are providing a range that is cost effective and high quality.”

Blackwoods is more than just a supplier—it’s a partner in safety. With decades of industry experience and a wide range of high-quality products, Blackwoods ensures businesses receive cost-effective, compliant, and comfortable workwear solutions.

Kim says one of the best parts of her job is working with the Blackwoods team, describing the culture as friendly and supportive—like a family.

“I really like working with the team. Everybody is really friendly, and Blackwoods is like a family.”

Outside of her role, Kim enjoys travelling and spending time with friends and family, bringing balance to her professional life.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

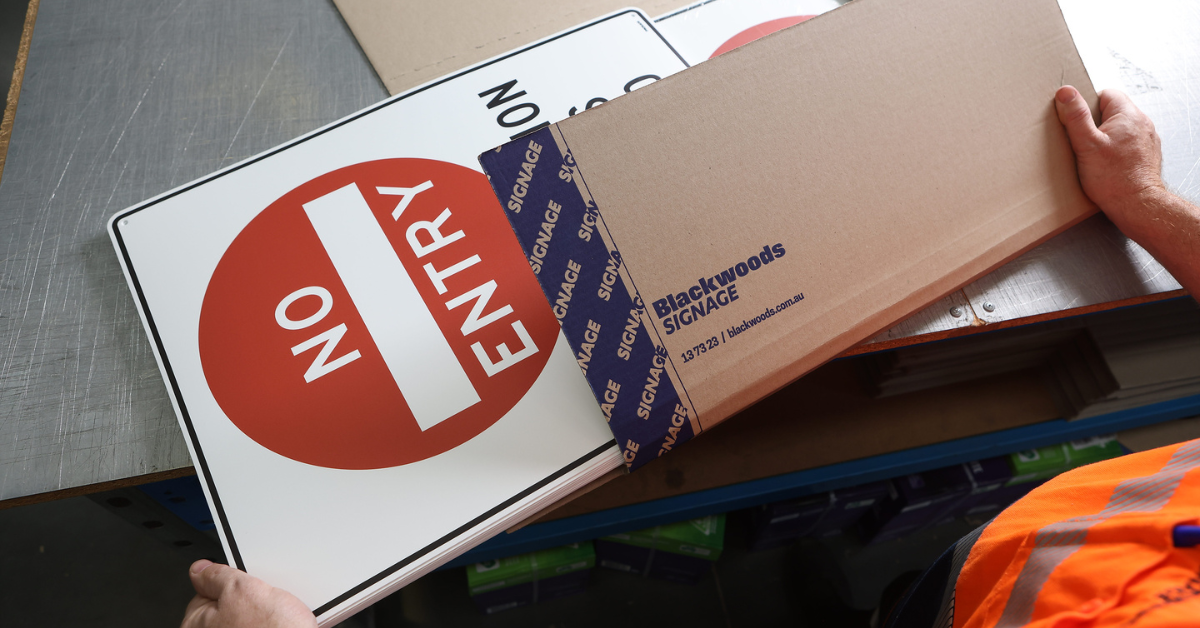

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...