How Loctite can help reduce equipment failure and downtime

Reliability and efficiency are crucial in the manufacturing industry. Yet Australian manufacturers often face unplanned downtime due to mechanical...

For generations, racing teams have been turning to LOCTITE solutions to keep their drivers safe and their cars winning on the track. The tradition continues in the innovative ABB FIA Formula E World Championship, with LOCTITE the Official Adhesive Partner for the TAG Heuer Porsche Formula E Team.

For generations, racing teams have been turning to LOCTITE solutions to keep their drivers safe and their cars winning on the track. The tradition continues in the innovative ABB FIA Formula E World Championship, with LOCTITE the Official Adhesive Partner for the TAG Heuer Porsche Formula E Team.

The partnership between Henkel, the manufacturer of LOCTITE products, and iconic carmaker Porsche, sees the companies collaborate not only on race day but in the development workshop.

How products are used by the team

Porsche Motorsport uses a range of LOCTITE products for more than 20 applications on its 99X electric. Solutions include epoxy adhesives, retaining compounds, gap-filling adhesives, structural adhesives, instant adhesives, thread sealants and threadlockers to ensure mechanical reliability for suspension bearings, gearbox housing parts, powertrain bolts and steering wheel components.

LOCTITE’s threadlockers resolve the issue of self-loosening stud bolts by filling the gaps in the thread. The adhesive seals are watertight, which means mechanical fasteners don’t rust in place.

Neil Board, national account manager for Henkel in Australia, says bolts coming loose within the suspension components of the vehicles is a key issue.

“They are under extreme vibration and stress loads, and traditional mechanical locking devices like spring washers and nyloc nuts don’t completely resolve that issue,” he says.

“They don’t stop the vibrational loosening whereas a LOCTITE threadlocker stops that component from coming loose and completely fills the gap within the threads, Loctite Threadlockers provide the added benefit of completely sealing out moisture and thus preventing corrosion, once again traditional mechanical locking devices cannot stop moisture ingress that leads to fasteners rusting in place.”

Porsche Motorsport also uses LOCTITE adhesives for panel bonding in manufacturing, reducing the weight of the car while strengthening the cockpit for added driver safety.

A range of products for different applications

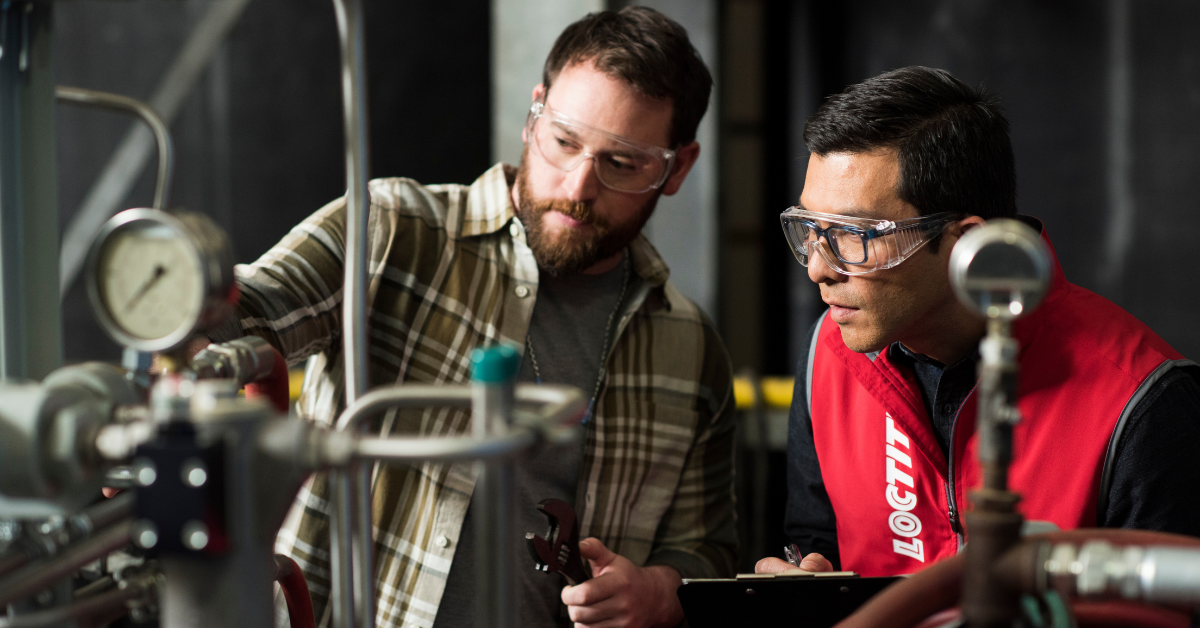

Providing the right adhesive for the right application area takes many complex factors into account in terms of materials, curing time and application method.

Applications beyond automotive

Henkel’s application engineers work with major auto companies around the world, including Porsche, GM and Ford.

Within Australia, they also consult to a wide range of clients in mining, defence, aerospace, construction and manufacturing to problem solve, recommend the right products and advise on the application.

Wherever there is mechanical assembly that uses threaded fasteners or retaining cylindrical applications, LOCTITE® ensures that components continue to function as they are meant to.

LOCTITE products are available at Blackwoods, Australia’s largest provider of industrial and safety equipment. Shop the LOCTITE range online or visit your local Blackwoods branch.

Reliability and efficiency are crucial in the manufacturing industry. Yet Australian manufacturers often face unplanned downtime due to mechanical...

In the world of heavy industry, downtime isn’t just a hassle—it’s a costly hit to productivity, safety, and team morale. Whether you're on the tools...

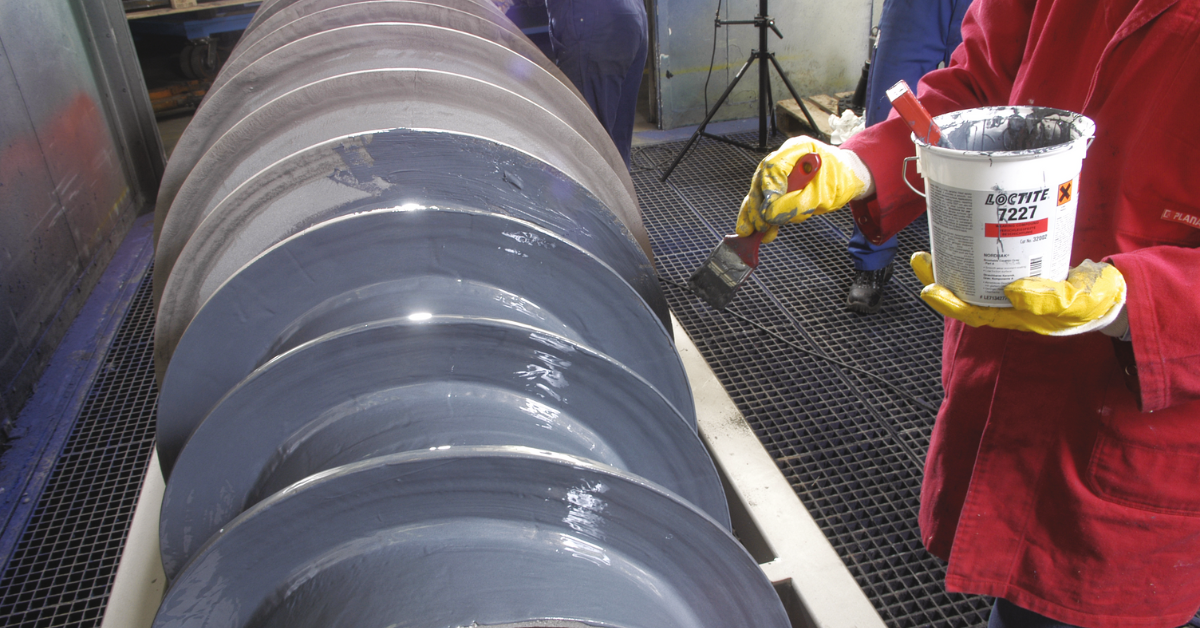

Mining operations such as minerals processing face extreme wear of critical equipment from abrasion, repetitive impact, erosion and chemical attack....