How Loctite can help reduce equipment failure and downtime

Reliability and efficiency are crucial in the manufacturing industry. Yet Australian manufacturers often face unplanned downtime due to mechanical...

1 min read

Loctite

:

19 November 2025

Loctite

:

19 November 2025

In the world of heavy industry, downtime isn’t just a hassle—it’s a costly hit to productivity, safety, and team morale. Whether you're on the tools in a workshop, managing a maintenance crew, or overseeing reliability across a site, keeping gear running smoothly is non-negotiable.

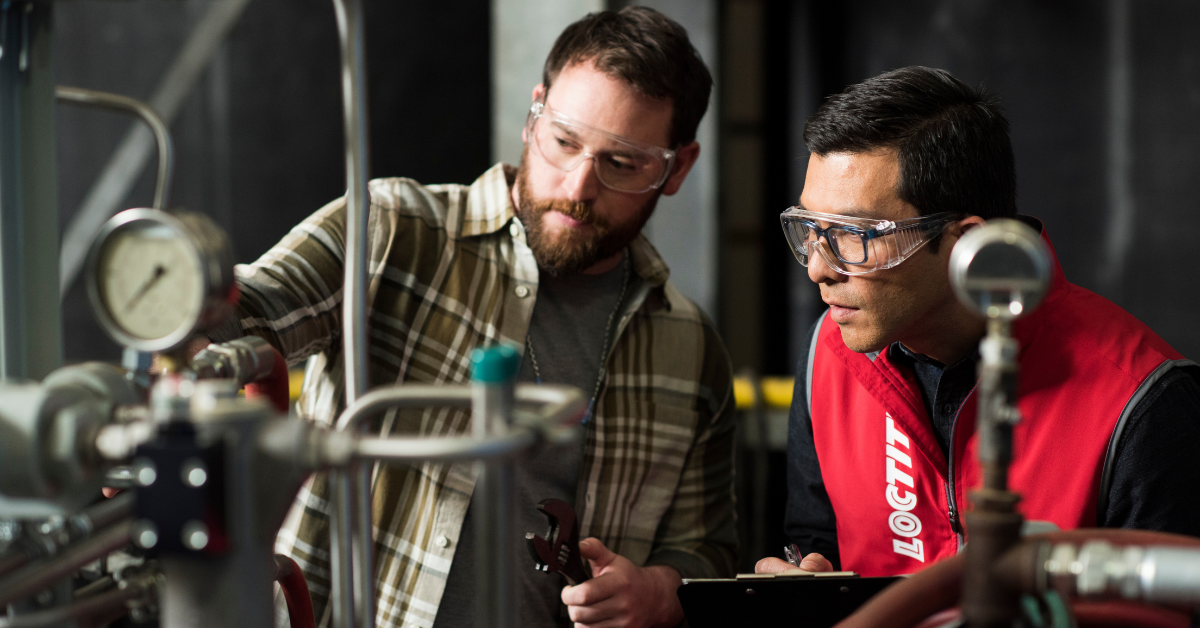

That’s why tradies, fitters, and maintenance managers across Australia trust Loctite, available through Blackwoods, to help prevent breakdowns before they happen.

From seized bolts and rusted threads to premature wear and tear, Aussie industrial environments are unforgiving. Heat, dust, vibration, and corrosive elements all take their toll—leading to unexpected stoppages, safety risks, and expensive repairs. For those responsible for keeping machinery humming, the question is simple: how do you stay ahead of the wear and tear?

Loctite’s range of Lubricants, Anti-Seize compounds, and Anaerobic adhesives are built for the harsh realities of Australian industry. Through Blackwoods, these products are easy to access, backed by expert advice, and proven to perform in the field.

Blackwoods is more than a supplier—we’re a partner in performance. When you choose Loctite through Blackwoods, you’re tapping into a network of expertise, reliability, and genuine support.

“At Loctite, our mission goes beyond supplying products. We’re here to help maintenance teams solve real problems. Through our partnership with Blackwoods, we’re making it easier than ever for Australian industries to access the right Adhesive solutions and support," says, Neil Board, National Account Manager Distribution, Henkel Australia

Explore the full range of Loctite Lubricants, Anti-Seize, and Anaerobic products available through Blackwoods. Partner with Loctite and Blackwoods to keep your equipment running stronger, longer.

Reliability and efficiency are crucial in the manufacturing industry. Yet Australian manufacturers often face unplanned downtime due to mechanical...

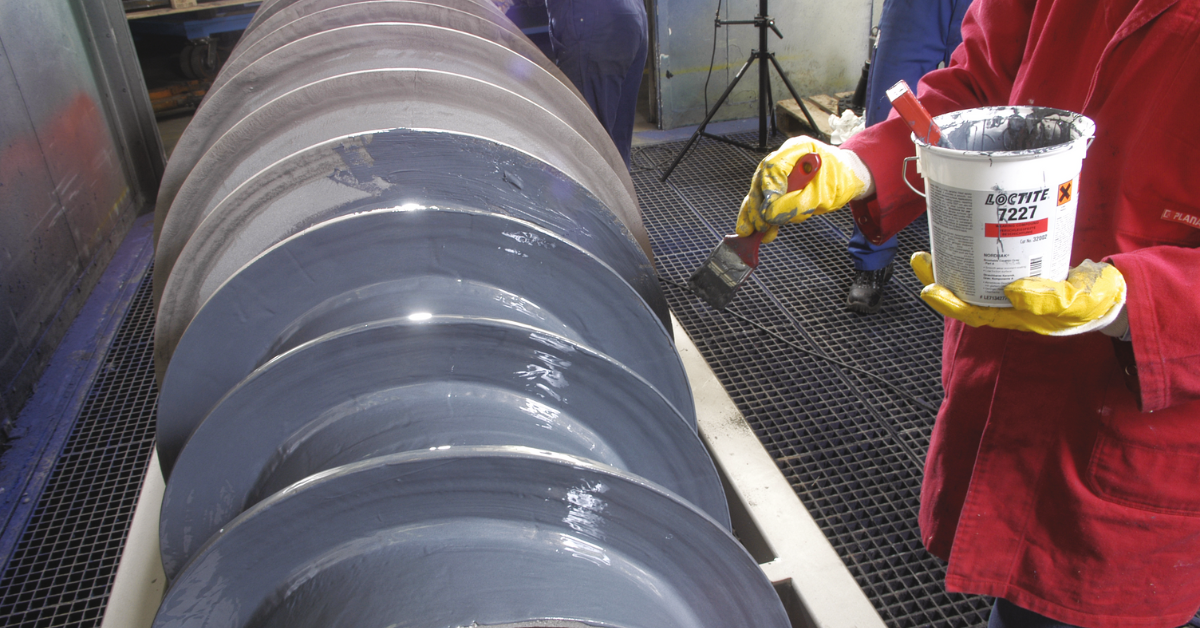

Mining operations such as minerals processing face extreme wear of critical equipment from abrasion, repetitive impact, erosion and chemical attack....

.png)

LOCTITE® wear-prevention coatings improve equipment longevity and minimise downtime. In industries like mining, power generation and steel...