Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

It is a little-known fact that confined spaces are leading contributors to workplace injuries. A confined space is generally an enclosed, or partially enclosed space that has features which can present potentially dangerous situations. For example, a space that has such conditions as low oxygen levels, unstable materials, contaminants that may cause fire or explosion, or harmful levels of airborne contaminants.

Commonly, people primarily link confined spaces with mining and manufacturing, but there are countless other workplaces of various sizes and locations that are also affected, including:

Commonly, people primarily link confined spaces with mining and manufacturing, but there are countless other workplaces of various sizes and locations that are also affected, including:

• Storage tanks and silos

• Pipes

• Manholes

• Elevator shafts

• Ducts

• Culverts

• Tunnels

• Alkylation units

• Trench boxes

• Utility vaults

• Reaction vessels

• Waste treatment facilities

• Maintenance of machines in a confined space

When identifying a confined space, the first step is to see whether the workspace being assessed fits the definitionof a ‘Confined Space’ as laid out in the WHS regulations, the Australian Standards, and the Code of Practice. However, “A workspace may not fit the definition laid out in the Standard exactly, but still could be regarded as a hazardous workspace requiring similar controls,” says Ash Mayor, Specialist Trainer and Assessor, 3M Safety and Training.

Confined spaces are areas that have been deemed to have met certain criteria: It is an enclosed or partially enclosed space which isn’t primarily designed to be occupied, is at normal atmospheric pressure while people are in it and is, or is likely to be a risk to health and safety due to an unsafe level of oxygen, or contains contaminants including gases, vapours or dusts which may cause fire or explosion, or a harmful concentration of airborne contaminants, or engulfment.

Consideration should be given to the number of people in a confined space and work being undertaken and duration of time in the space. “Hazards arising from manual tasks may be exacerbated by physical constraints when working

in a confined space. This also can include PPE (Personal Protective Equipment) which can restrict mobility,” says

Nick Stinziani, Business Development Manager – Fall Protection, MSA Safety Australia. “Selection and use of approved, fit-for purpose PPE is of critical importance, and personnel involved in confined space operations must be fully

trained in the correct use and maintenance of all related PPE, monitoring and rescue equipment. MSA are able to provide training in this area.

The purpose of a risk assessment is to:

1. Identify potential hazards

2. Identify the tasks that are required to perform the job

3. Review methods used to complete the tasks

4. Identify the hazards involved and the associated risks related to the method required to complete the task

5. Creation of emergency response procedures

6. Assess the competence of workers to perform the task

When we have confined spaces in our workplaces, we must adhere to appropriate risk assessment processes and follow the definitions provided by Safework Australia’s, Confined Spaces Code of Practice, Regulation 5. Risk assessments come in various forms including JHA (Job Hazard Analysis) or SWMS (Safe Work Method Statement).

“The WHS Regulations require employers to work through the hierarchy of control measures when managing certain risks, such as confined space operations. The hierarchy of control is a system for controlling risks, using a step-by-step approach to eliminate or reduce risks, ranking it from the highest level of protection to the lowest, or least reliable,” says Nick.

Further guidance on the risk management process and the hierarchy of control measures is in the Code of Practice: How to manage work health and safety risks. Rescue Plans must also be in place. These include:

• Site evaluation

• Identification of proper safety equipment and other required tools, which may include ‘intrinsically safe’ tools and equipment for use in hazardous atmospheres.

• A trained rescue team that knows what procedures to follow should they be required.

• Accredited training that involves practice and hands-on experience for all parties who will work in and around the confined space.

“Workers must be properly trained to work in confined spaces, that at a minimum complies with Regulation 76 of the Code of Practice. We provide nationally accredited training for confined space work including, Enter and Work in Confined Space, Gas Test Atmospheres, Operate Breathing Apparatus Along with practical rescue scenario training

to ensure that rescue plans are tested, rehearsed and effective. This may include a trained ‘rescue team’ on stand-by, or the workers being trained and able to conduct an autonomous rescue without relying on emergency services,” says Ash.

A Rescue Plan must be a dynamic document that can readily adapt to changing situations. Also, employers

must understand and acknowledge the relevant National and State Standards, as per Regulation 74 of the Code of

Practice. Confined space operations can be hazardous and complicated. There is a lot to consider. “It is essential the appropriate equipment is used, procedures are followed, and workers are aware of the specific risks, are trained and

competent in use of equipment and procedures,” says Darren Gallagher, National Category Manager - Workplace Safety, Blackwoods.

“That said, our Technical Safety Specialists, along with our supply partners MSA Safety and 3M are here to provide

customers with right equipment and access to certified training and awareness seminars.”

DID YOU KNOW:

REGULATION 74: A person conducting a business or undertaking must establish first aid and rescue procedures to be followed in an emergency and ensure those procedures are practised as necessary to ensure that they are efficient and effective. First aid and rescue procedures must be initiated from outside the confined space as soon as practicable

in an emergency. The person conducting a business or undertaking must also ensure that openings for entry and exit are of a sufficient size to allow emergency access; openings are not obstructed; and any plant, equipment and personal protective equipment provided for first aid or emergency rescue are maintained in good working order.

REGULATION 76: The training provided to relevant workers must cover:

• the nature of all hazards associated with a confined space.

• the need for, and appropriate use of, risk control measures.

• the selection, use, fit, testing and storage of any personal protective equipment.

• the contents of any relevant confined space entry permit.

Confined Spaces Code of Practice - Safe Work Australia

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

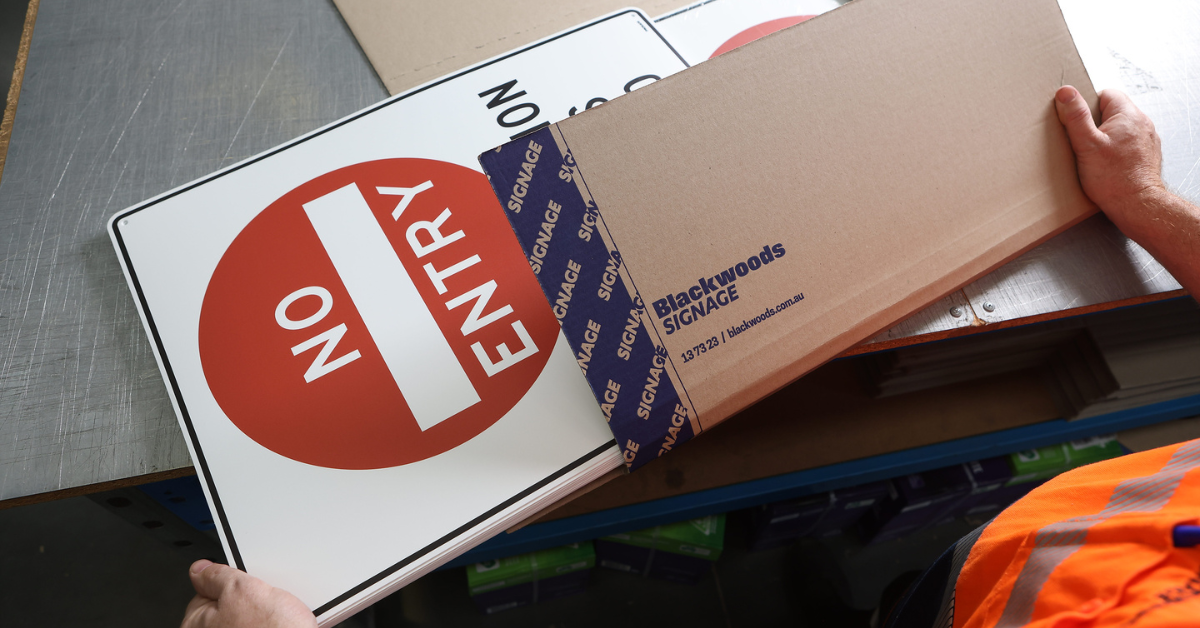

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...