Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

2 min read

Blackwoods

:

19 November 2025

Blackwoods

:

19 November 2025

In high-risk industries like waste management, protective eyewear isn’t just a requirement — it’s a frontline defence against injury. When a leading waste management company identified inconsistencies in its safety eyewear usage, it took decisive action. The goal: ensure every team-member was equipped with compliant, task-appropriate eyewear, eliminate the risk of incorrect product selection, and improve safety outcomes through education.

But with a diverse workforce operating across multiple sites — including customer premises — the challenge was anything but straightforward.

The company’s operations span a wide range of environments and tasks, from waste sorting and transport to on-site customer services. This diversity had led to a proliferation of safety eyewear variants — some compliant, some not — and limited visibility into how eyewear was being used in the field.

To solve this, the company needed a supply partner who could:

This wasn’t just about rationalising inventory — it was about protecting people.

As a preferred supplier, Blackwoods partnered closely with the company to define clear objectives and success measures. The process began with a full review of all safety eyewear in use, followed by a detailed risk assessment that matched eyewear types to tasks, environments, and applicable standards.

From this analysis, Blackwoods identified opportunities to consolidate eyewear variants and presented a streamlined, compliant range tailored to the company’s operational needs.

To ensure the solution worked in practice, Blackwoods led team-member wear trials for all new or updated products. These trials validated product performance, comfort, and compliance — ensuring no compromise on safety or fit.

Toolbox talks were rolled out across the business to educate team-members on the changes, reinforcing correct selection and use in every environment.

“…conducting a thorough assessment of the end-user and operator profiles was critical to success given the various face shapes and sizes. This ensured we were able to deliver a solution that met everyone’s needs without compromising the safety of any individual," says Craig Postill, Technical Specialist, Blackwoods

Blackwoods delivered a solution that was not only safer — but smarter. The company now operates with a rationalised, approved safety eyewear range that meets all applicable standards and supports every task and environment.

Key benefits included:

Blackwoods brings more than products — it brings perspective. With deep technical expertise, access to Australia’s leading safety brands, and a collaborative approach, Blackwoods helps businesses turn safety challenges into strategic wins.

From risk assessments and product trials to education and implementation, Blackwoods delivers end-to-end solutions that protect people and empower operations.

Contact Blackwoods today to discover how our tailored solutions can keep your business safe.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

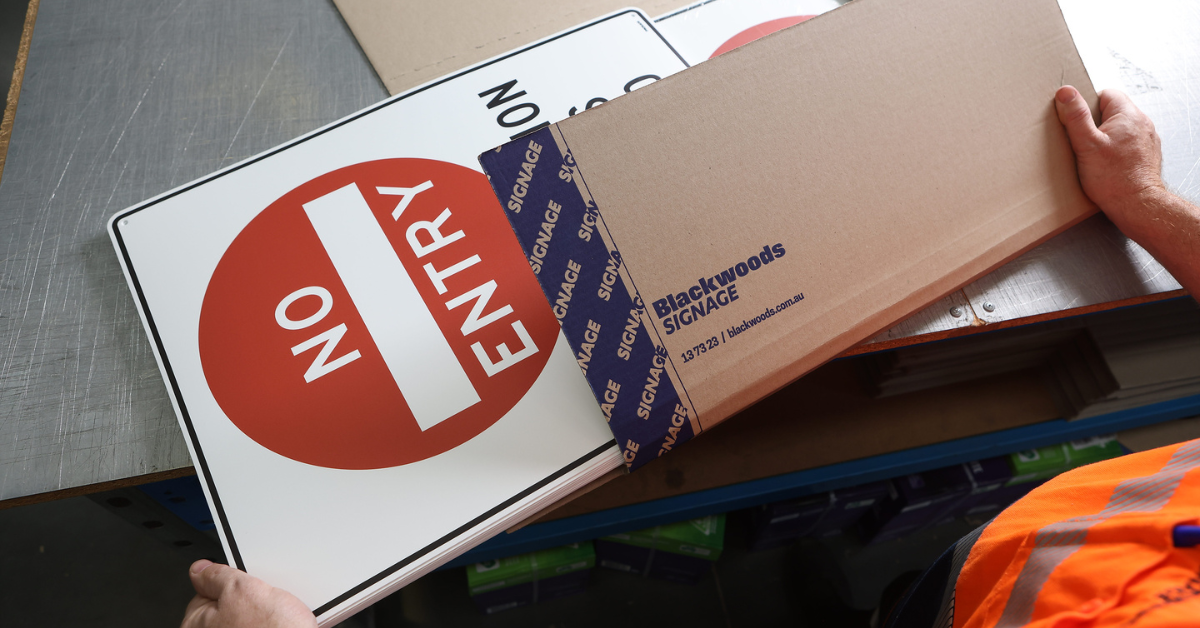

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...