Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

2 min read

Blackwoods

:

19 November 2025

Blackwoods

:

19 November 2025

In fast-paced manufacturing environments, minor hand injuries can quickly become a major concern. For one leading manufacturing company, repetitive hand injuries were not only affecting team-member wellbeing — they were threatening productivity and operational efficiency. The company needed a solution that could move fast, deliver results, and protect its people without slowing down its processes.

That’s where Blackwoods stepped in.

The company’s operations involved a wide range of tasks and applications, each with its own risk profile. With operators working across multiple functions and environments, identifying the root causes of hand injuries — and implementing a solution — required more than just protective gear. It demanded:

The goal was clear: reduce minor hand injuries through correct product selection and increased operator compliance — all without impacting productivity.

As a trusted advisor and supply partner, Blackwoods worked closely with the company’s safety and operational teams to launch a series of collaborative workshops. These sessions, combined with direct operator interviews, helped uncover the root causes of injuries and establish clear success measures.

From there, Blackwoods led targeted product wear trials to validate glove selection and performance in real-world conditions. These trials ensured that every recommendation was not only technically sound — but comfortable, practical, and fit for purpose.

Toolbox talks were rolled out across the business to educate operators on the changes, reinforce correct usage, and build buy-in from the ground up.

“…early engagement with the end users and operators was essential to accurately understanding the needs, solving the challenge, and obtaining the necessary buy-in to deliver a successful outcome at the end of the process,” says Drew Dauncey, Technical Specialist, Blackwoods.

Blackwoods delivered a solution that was both strategic and sustainable. The company now operates with a validated, task-specific hand protection matrix that empowers operators to choose the right protection for every job — reducing injuries and improving compliance.

Key benefits included:

Blackwoods doesn’t just supply safety products — it delivers safety outcomes. With decades of experience, technical depth, and access to Australia’s leading safety brands, Blackwoods helps businesses turn risk into resilience.

From root cause analysis and product trials to education and implementation, Blackwoods is your partner in building safer, smarter workplaces.

Contact Blackwoods today to discover how our tailored solutions can keep your business safe.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

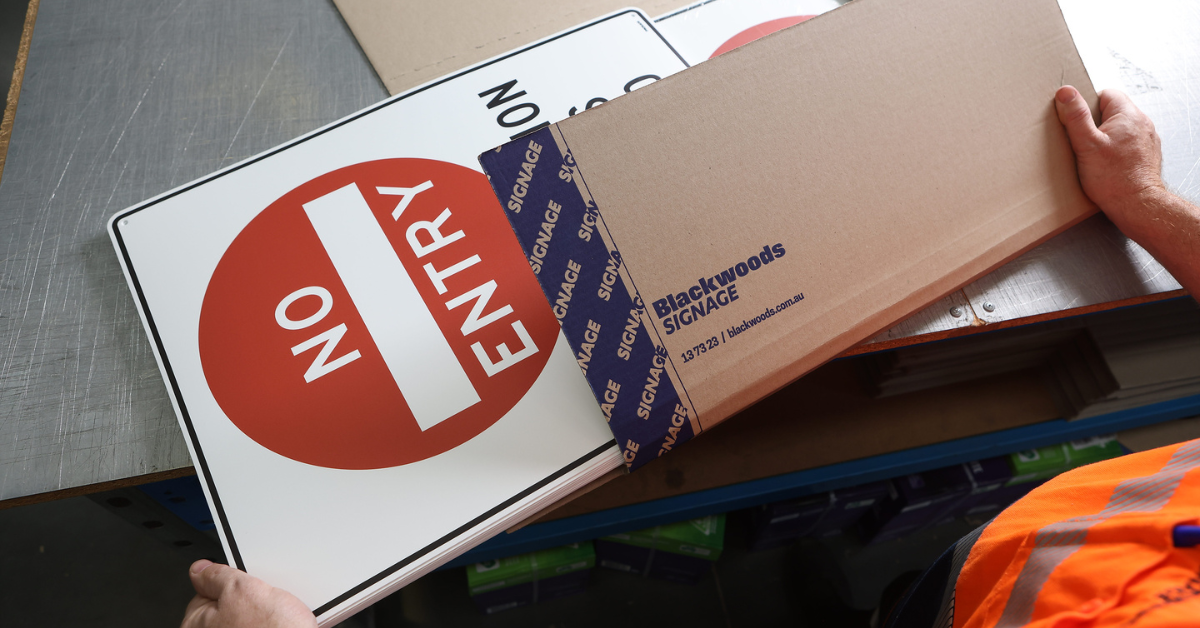

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...