Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

2 min read

Blackwoods

:

19 November 2025

Blackwoods

:

19 November 2025

When the Australian Workplace Exposure Standard (WES) for welding fumes was revised, one fabrication company faced an urgent challenge: reassess its operations to ensure team-member safety and regulatory compliance. Welding fumes, if not properly controlled, pose serious health risks — and the new standard demanded immediate action. The company needed more than just equipment; it needed expertise, insight, and a partner who could translate regulation into real-world safety outcomes.

The stakes were high. The company required a supply partner with deep technical knowledge of welding and fume extraction, a clear understanding of the revised WES, and access to a robust network of trusted brands and suppliers. Crucially, any solution had to be practical — enhancing safety without disrupting production or compromising operational efficiency.

This wasn’t just about ticking a compliance box. It was about safeguarding people while keeping business moving.

Blackwoods stepped in with a consultative, boots-on-the-ground approach. After presenting the implications of the new WES to the company’s leadership, Blackwoods conducted a comprehensive review of all welding activities on-site. This included:

From this review, Blackwoods presented a range of tailored recommendations — from fixed to mobile fume extraction solutions — each grounded in technical data and operational feasibility.

The company chose a mobile fume extraction unit, valuing its flexibility and effectiveness. Blackwoods coordinated with a third-party supplier to deliver an in situ demonstration, ensuring the unit’s functionality aligned with the company’s needs. Toolbox talks and hands-on training followed, empowering team-members to use the equipment confidently and correctly.

Blackwoods isn’t just a supplier — it’s a safety partner. With decades of industry experience, a national footprint, and access to leading brands, Blackwoods brings together technical expertise and practical know-how to solve complex safety challenges. From compliance consulting to product validation and training, Blackwoods delivers end-to-end solutions that work.

As Paul Cartmell, Blackwoods Technical Specialist, put it:

“…whilst changes to Standards are not common, they are extremely important for maintaining operator safety and safe workplaces. The opportunity to work collaboratively with a customer to understand the impact of any Standards change, and to identify and implement a solution – is highly rewarding.”

Thanks to Blackwoods, the company achieved:

In a landscape where standards evolve and risks persist; safety is not a one-time fix — it’s a continuous commitment. Blackwoods’ collaborative approach, technical depth, and customer-first mindset make it the partner of choice for businesses navigating change. Because when safety is on the line, expertise matters.

Contact Blackwoods today to discover how our tailored solutions can keep your business safe.

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

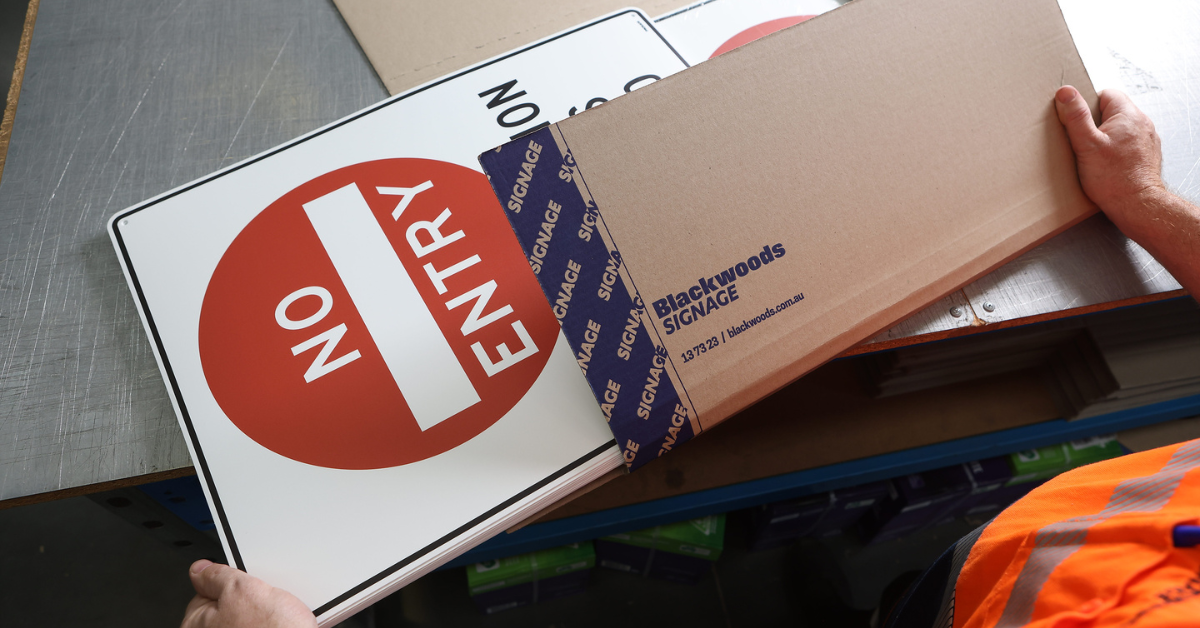

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...