Back to work featuring our recommended products

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

How do we best care for our world, particularly its people, environment, and climate? This is one of the most important and pressing issues of our age.

As a socially responsible company, Blackwoods has embedded sustainable business practices and is committed to creating a positive impact on our people, product, community, and the environment.

“At Blackwoods we are committed to reducing the emissions intensity of our business and improving our resilience to climate change. We are actively working towards achieving zero waste to landfill by 2032 and adopting a more circular economy.”

Australia is the second-largest consumer of textiles per capita in the world, with more than 800,000 tonnes of clothing ending up in landfills each year.*

With this in mind, Blackwoods is continually researching and investing in understanding new technologies and global trends in order to deliver a more sustainable apparel product range. One such innovation is to use recycled materials in selected garments.

Using recycled materials gives material waste a new life while helping to reduce environmental impacts compared to land filling and incineration of old materials that could otherwise be recycled.**

To ensure responsible use of recycled materials, an internationally recognised standard, The Global Recycles Standard (GRS) has been adopted by Blackwoods. Under these standards, the fabric has been made with at least 20-100% recycled materials, uses environmentally and socially responsible manufacturing processes, and is independently certified within the supply chain.

Other alternates are branded recycled fibre technology innovators that ensure part or all production of the fibre is made in a circular system such as using renewable energy and recycled wastewater further reducing emissions and water impact.

Blackwoods’ exclusive brand Workhorse has launched a high vis vest made from post consumer recycled polyester. The high vis vest contains recycled polyester (excluding trims, labels, and reflective tape) which is made from post consumer

plastic waste that otherwise would have gone into landfill.

To ensure these recycling practices are responsible, we have sourced our vest from factories that have been verified at each stage of the supply chain. The facilities from source to final supplier have met social and environmental requirements and we regularly audit our suppliers to verify the source of the polyester.

Recycled polyester uses up waste and reduces our need for virgin fibres, and (depending on the recycling technique used) can still have the same quality as virgin fibre. ***

It can be from post-consumer waste or pre-consumer waste, or a mix of both. Post-consumer textile waste is preferred, as, under circular design, pre-consumer waste should be minimised.

We are living in fast-changing times, and it’s up to all of us to keep pace with what is happening. When it comes to clothing, if we are all more conscious of the choices we make, we can make a difference.

-1.png?width=784&name=MicrosoftTeams-image%20(31)-1.png)

Note: Post consumer plastic waste is any form of plastic waste that has reached its end of life after consumer use such as plastic bottles, consumer packaging that is then collected and further recycled created creating a new usage.

* Source: Australian Government; Department of Agriculture, Water and the Environment

** Source: G. Sandin, G.M. Peters. Environmental impact of textile reuse and recycling – A review. J. Clean. Prod., 184 (2018), pp.353-365, 10.1016/j.jclepro.2018.02.266

*** Source: Rex, D., (Okcabol, S., and Roos, S. (2019). Possible sustainable fibers on the market and their technical properties: The Fiber Bible Part 1. MISTRA Future Fashion

Revitalising your projects with industry-leading solutions As worksites across Australia gear up for a busy season, having the right gear is...

The challenge: Inefficient inventory and lost productivity. Two large manufacturing facilities were facing mounting challenges in managing their...

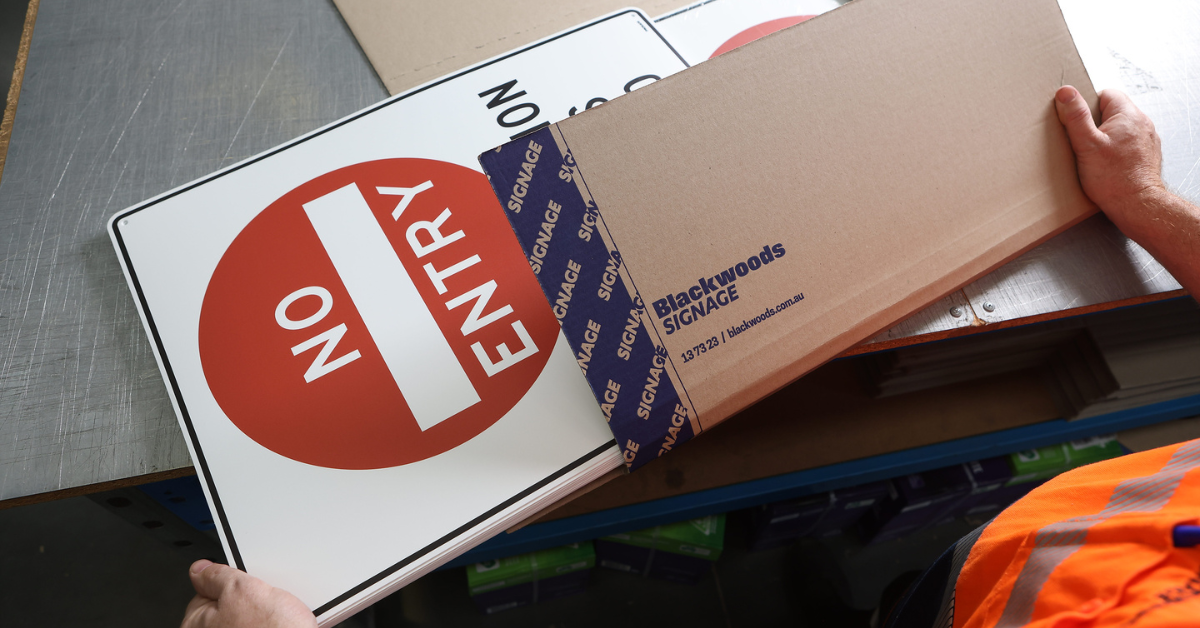

Signage provides vital communication in fast-paced manufacturing environments. Productivity, efficiency and safety depend on well-organised...