Peak performance. Unmatched style. Eyewear without limits.

In high-risk environments, safety eyewear isn’t optional — it’s essential. But today’s workforce demands more than just protection. They want eyewear...

Following the inclusion of a performance standard for back of hand impact protection in the revised EN388 2016, the American National Standards Institute, ANSI, followed suite and adopted ISEA 138 testing and rating the performance of back of hand impact protection on safety gloves.

Published February 27, 2019, the ISEA (International Safety Equipment Association) 138 standard establishes the minimum performance, classification and labelling requirements for gloves that are designed to protect the knuckles and fingers from impacts. This will help safety professionals make better-informed decisions about glove selection – ultimately keeping more people safe on the job.

One pair of gloves is required per test. The gloves are cut in half, and the back-of-hand potion is placed on an anvil. A striker with a force of 5 joules is dropped on the required back-of-hand locations. The amount of force transferred through the glove back-of-hand is recorded with a force gauge that is connected below the anvil.

One major difference between ISEA 138 and EN388 is that for ISEA 138 the impacts are repeated for both left and right hands of the glove, giving 18 impacts in total, compared to EN388 requirement for 4 impacts on the knuckles only.

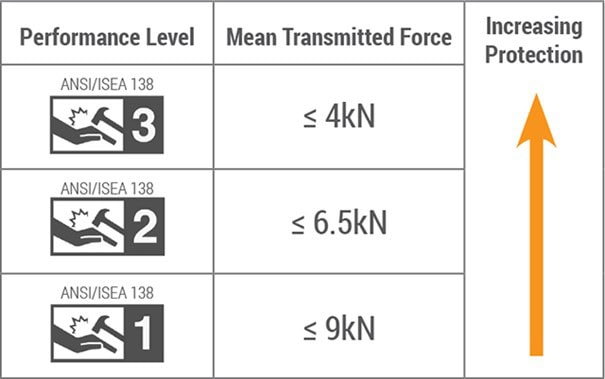

The ISEA 138 will test two areas for impact performance: knuckles and fingers/thumb. On both gloves, knuckles are tested four times while fingers/ thumb are tested five times. The average of the knuckle tests is compared to the average of the ten finger tests. The highest average of the two (the highest amount of force transferred which delivers a lower score) is the final impact testing score. This chart, which includes glove markings, showcases the performance levels, with “Performance Level 3” being the highest.

Although the EN388 testing method is similar, the testing areas and scoring are quite different. EN388 only tests the impact on the knuckles and are given a pass or fail score – no performance levels.

Whereas the ISEA 138 tests on all fingers and knuckles and are rated with performance levels 1-3. This inclusion of fingers is critical for industrial glove users, whose fingers are usually at high risk for injury. With a performance level scale, workers can make better-informed decisions as to what type of glove will give them the appropriate level of impact protection based on the hazards they may face.

uvex safety Australia offers impact-resistant gloves designed to withstand higher levels of impact. Choose from our range of impact protection gloves as per your requirement.

In high-risk environments, safety eyewear isn’t optional — it’s essential. But today’s workforce demands more than just protection. They want eyewear...

In food production plants, workers are exposed to the constant noise of mixers, conveyor systems and other manufacturing equipment. Earplugs are a...

The statistics on workplace hearing damage make for grim reading. Hearing Australia’s Principal Audiologist, Karen Hirschausen says “more than 1.1...