Workers are exposed to many hazardous fine particles in the workplace. For example, asbestos and crystalline silica are types of hazardous fine particles prevalent in workplaces in Australia for many years and cause serious health effects on inhalation including silicosis, mesothelioma and lung cancer. Workers can unknowingly bring home these hazardous substances on their clothes, shoes, skin, tools and vehicle interiors, thus exposing family members to these toxins.

Regulations require that disposable protective coveralls for handling hazardous particles meet the EN13982-1 Type 5 standard. As the Total Inward Leakage (TILA) allowed under this standard is high (15% in 8 out of 10 suits tested); a more stringent standard of EN1073-2 Class 2 which requires Average TILA to be less than 2% for 6 suits tested is desirable.

Workers using coveralls that meet the EN13982-1 Type 5 Standard may be unaware that up to 15% of the hazardous fine particles may be entering inside the suit. If appropriate decontamination procedures are not implemented, it can lead to secondary inhalation of asbestos and silica particles by the worker and family members if contaminated garments worn under the coveralls are worn home.

The Tyvek® Classic Xpert Advantage

One way workers can reduce the risk of exposure to these toxins is to wear disposable coveralls that provide effective holdout to these hazardous fine particles. Tyvek® Classic Xpert Coveralls provide protection against hazardous fine particles 15 times better than the Type 5 Standard, allowing only 1% inward leakage.

Tyvek® Protective Apparel provides superior protection for workers. Companies around the world use more than 200 million Tyvek® garments per year. Tyvek® garments have been used to support emergency response efforts across the globe, including the U.S. Deepwater Horizon oil spill cleanup; Fukushima nuclear plant remediation; and for protection of workers in West Africa during Ebola crisis.

It is critical to have the highest level of protection against hazardous fine particles to ensure worker safety. It is equally important that not just new garments provide protection, but garments are engineered to provide protection all day. Tyvek® Classic Xpert offers superior protection and a balance of comfort and durability in most demanding applications.

DuPont™ Tyvek® Protective Apparel

Manufactured only by DuPont™ using a unique flash-spinning process, Tyvek® fabric is made of strong, continuous, high density polyethylene fibers. Tyvek® is a soft fabric that is intrinsically breathable, is low-linting and has inherent barrier properties making it an ideal fabric for a wide range of protective applications.

Comparison of DuPont™ Tyvek® with other single use coverall fabrics

Microporous film (MPF) fabrics comprise of a thin microporous film bonded to a spunbound polypropylene base. MPF offers limited durability since protection is lost when the protective film layer is abraded.

The performance of Spunbound/Meltblown/Spunbound (SMS) fabrics relies on a meltblown polypropylene layer sandwiched between two open polypropylene layers. SMS fabrics suffer from limited durability and relatively weak barrier performance due to their relatively open fiber structure. In addition, their high air permeability significantly compromises barrier properties making them only really appropriate for very basic protection.

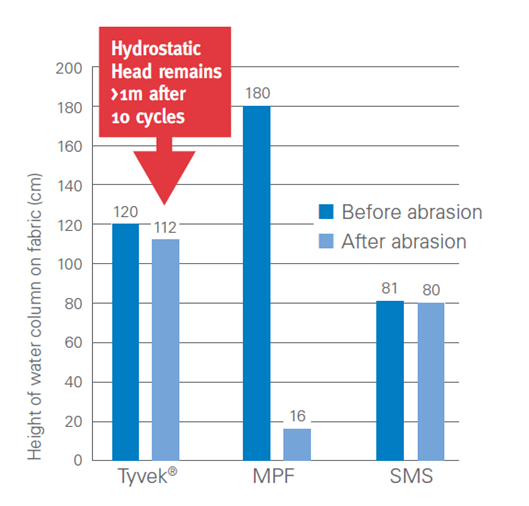

Abrasion can seriously undermine the protective efficiency of a fabric. Fabrics that rely on thin film (MPF) or have an inherently weak physical structure (SMS) can quickly and easily lose their resistance to penetration under operating conditions.

This phenomenon can be demonstrated by a hydrostatic pressure test which measures liquid barrier performance. Prior to the abrasion test, MPF fabric offers the best resistance to liquid pressure. But after just 10 cycles of abrasion, its performance takes a spectacular dive, while SMS is less affected but offers much lower performance level. After abrasion, Tyvek® penetration performance is the highest.

Total Inward Leakage: When comparing the barrier performance of DuPont™ Tyvek® Classic Xpert coveralls with other Type 5 suits made of MPF and SMS, Tyvek® shows a significantly lower Average Total Inward Leakage (TILA) according to EN ISO 13982-2 with an average value of less than 1%.

Total Inward Leakage (TILA): Average of the 10 suits and all activities EN ISO 13982 - (1 and 2).

Implementing a strong “Last Line of Defence” at Your Work Site

Regulations require that disposable protective coveralls for handling hazardous particles meet the EN 13982-1Type 5 standard. However, as the Total Inward Leakage (TILA) allowed under this standard is very high (15% in 8 out of 10 suits tested); the more stringent standard of EN 1073-2 Class 2 is desirable, as this requires the Average TILA to

be less than 2% for 6 suits tested.

The Tyvek® barrier fabric from DuPont is a proprietary non-woven material. Tyvek® is formed from High Density Polyethylene (HDPE) ultrafine continuous fibres which are laid down into a tough, light, homogeneous fabric with inherent vapour breathability characteristics on account of its microscopic lattice structure.

This inherent ability to evacuate body moisture, whilst still providing excellent particle holdout, provides the ideal balance of comfort and protection against silica, asbestos and other fine particle hazards.