Elevate worker safety with platform ladders

Using traditional double-sided ladders on the job site can potentially leave workers facing an increased risk of falls. How?

2 min read

Bailey Ladders

:

27 October 2025

Bailey Ladders

:

27 October 2025

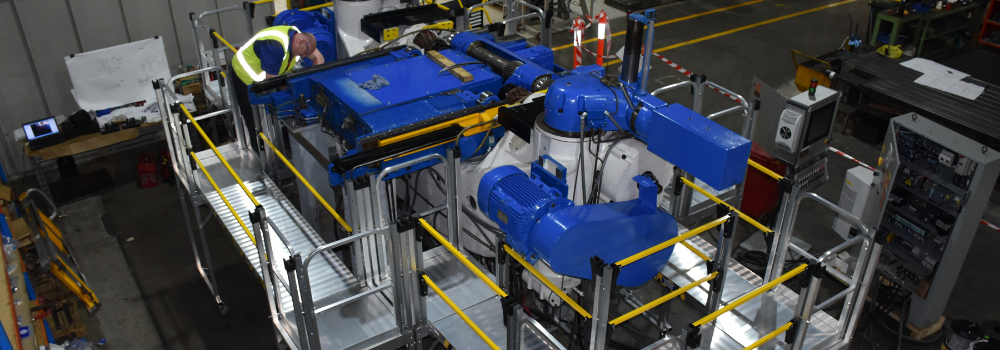

Across the manufacturing industry, safe height access to machinery and process lines is key. Traditional access solutions generally involve fixed platforms and ladders - built and installed for a single use, in a single position.

But these solutions come with limitations - they can’t be moved around to access different spaces, and components can’t be added or removed as access needs change.

Custom-built platforms can be expensive, and the lead times for ordering and installing, as well as for replacement if a part breaks, can be lengthy. Bailey’s Access Platform and Modular Access System (MAS) offer high-quality temporary work platforms that are off-the-shelf, scalable and easily moveable for the optimum safety and access.

Bailey’s Access Platform, made from heavy-duty fully welded aluminium, provides the ability to work safely at a variety of heights - options range from three steps up to fourteen. Employees can work from three sides of the platform, safely enclosed by safety gates and handrails.

The Access Platform is built on large 125mm ‘easy glide’ wheels, so it can be moved to any part of the facility as needed. It provides both a fixed leg and locked wheel option for extra stability once in place through an engage/disengage handle.

The Access Platform can also form the basis of a MAS, which allows for additional working room. The MAS can be expanded in a range of configurations and heights. With a variety of platforms (bridges), joiners, uprights and platform spreaders available, the MAS is designed to be easily customisable to suit the particular application.

It can be built in complex shapes at a variety of heights, and can be broken down and rebuilt in different configurations and sizes as needs change. The side railings can be removed for easier task access. The system is designed for high frequency, heavy-duty work, but with all modules built on locking castors, it’s still lightweight and easy to move around the workspace.

Because the elements of the MAS are easily available, there’s no need to design an access system, send away for it, and wait for weeks for a custom platform. Order the components, and build the system according to the job requirements.

The availability of parts in the modular system also means quick and easy replacement if a piece is damaged. If a forklift backs into a leg on a fixed system for example, it will likely need to be cut out and a new one manufactured and bolted or welded in. With the MAS, just order the part or keep replacements handy.

Stephen Laughlan, Marketing Manager of Werner Co Australia, says fixed access solutions need to be designed and engineered, which is hugely expensive, and once installed, they can only be used for one task.

In contrast, the MAS delivers an off-the-shelf solution that is customisable to the user’s unique requirements, and cost effective, because businesses can start small and continue to build the solution as requirements are identified.

“These systems are more flexible and more cost effective with a shorter lead time from order than a fixed structure,” he says. “It’s a great solution for varied and unique requirements, with an added advantage of being able to stagger the capex expenditure for the business.”

As Australia’s largest provider of industrial and safety equipment, Blackwoods has all your job requirements covered. Shop the Bailey range of Access Platforms and Modular Access Systems online, or contact your local Blackwoods representative to get a quote on a custom configuration.

Using traditional double-sided ladders on the job site can potentially leave workers facing an increased risk of falls. How?