If hazardous dust is part of your workplace, you need to apply measures set out by the Hierarchy of Controls which include Elimination, Substitution, Isolation, Engineering, and Administrative and Personal Protective Equipment. As part of the Engineering stage, it is essential to use the appropriate vacuum cleaner. This means the equipment is designed and rated to ensure dust is safely captured and contained.

Under the binding Australian Standard for vacuum cleaners, AS/NZS 60335-2-69:2017, dusts are categorised according to the level of danger they present in the workplace:

L- Class: Only slightly hazardous, and no special precautions for disposal.

M-Class: Hazardous and must be disposed of with low dust development.

H-Class: Extremely hazardous. Carcinogenic and pathogenic. Dust-free disposal.

Any workplace which has respirable crystalline silica (RCS) requires a vacuum cleaner with an H-Class rating. As with all equipment, make sure the relevant workers are properly trained and informed in how to use the vacuum cleaner.

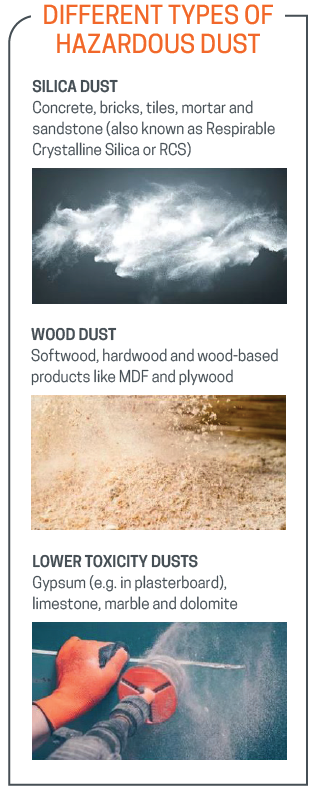

Of course, not all dust is the same. It can vary in particle size, shape, composition and physical properties.

It is the duty of employers and workers to know and understand the different dusts that are prevalent in their workplace, and then take the appropriate safety measures.

Related Posts:

Karcher

Karcher